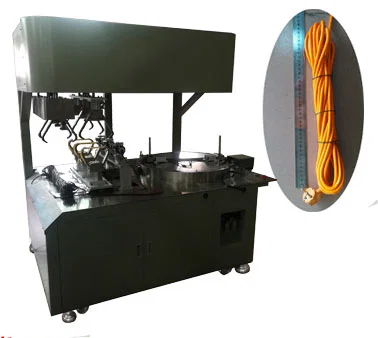

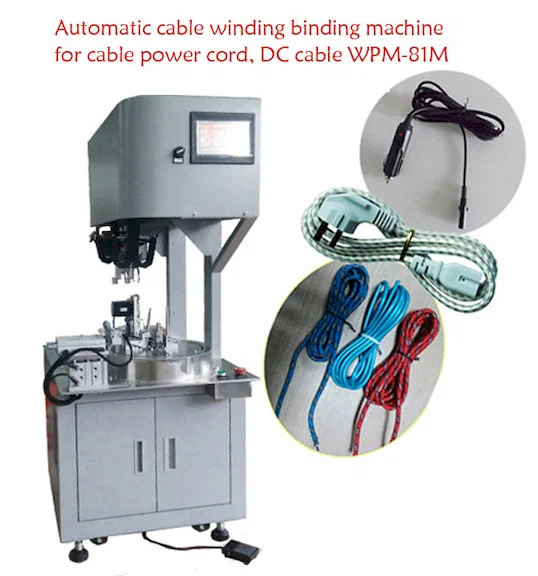

Small 8 type single tie type automatic winding and tie machine WPM-RT-81S

Technical parameters:

Suitable for AC/DC/USB cable

Winding appearance small 8-figure single cable tie

Applicable line length ≤3 m(depending on the line of sight)

Applicable wire diameter ≤ φ 4 mm

The spacing of winding is 45-80mm

Binding diameter ≤20 mm

The head length is 0-130 mm

Tail length >0 mm

Production efficiency 1800PCS /h (1-meter line length, 3 turns, outcrop, and outcrop)

Applicable binding tape-coated iron core ≤ 7.5kg/roll

Applicable pressure 0.55-0.65Mpa

Applicable voltage 220V 50Hz

Machine power ≤2800W

The machine size is about 1040L*720W*1540H mm

The weight of the machine is about 210KG