- Cable Coiling & Binding

- Tape Winding Machine

- Semi-Auto Wire Brush Machine

- Wire Cutting & Stripping

- Semi-Auto Crimping Machine

- Wire Stripper Crimper Blades

- Terminal Tensile Tester

- Cut-Off Machine

- Cable Labeling Machine

- Strapping Banding Tool

- Wire Terminals & Connectors

- Automated Tape Dispenser

- Automatic Wire Crimping Machine

- Terminal Crimping Tools

- Automatic Wire Feeder

- Automatic Soldering Machine

- Nylon Cable Tie Machine

- Injection Molding Machine

- Brazing & Welding Machine

- Screw Fastening Machine

- Power Cord Crimping Machine

- Wire Harness Tester

- Glue Dispensing Robot

- Wire Harness Packing Materials

New products

Home > Industry news

How to operate wire stripping and terminal crimping machine

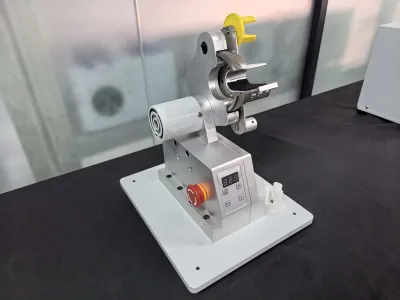

Terminal wire stripping and crimping machines WPM-2008A2

User’s ManualThank you for purchasing our WPM-2008A2 Wire Stripping Crimping Machine.

Before using the machine, the user must read the user manual carefully, and pay enough attention to safety. Please use the machine properly. The wrong operation will result in surprising trouble or shorten the product's service life, lowering the functions. Therefore please pay attention.

Notice:

1. The purpose of this manual lies in telling the operator about the basic standards, and please obey them during the usage or maintenance of the machine.

2. Users must use, repair, and maintain this machine only after fully understanding the contents of this user manual before using the machine.

3. The machine can be installed only by the entitled personnel.

4. Obey the following instructions at any time, if the manual isn't understood, please consult with the manufacturer.

5. To make that machine work stably and normally, we suggest the customer use a mano stat power supply.

6. The adoption of appropriate power supply incoming lines and good grounding are recommended.

7. Please deliver this user manual to the next proprietor, together with the machine, if this machine is transferred to other people.

8. Please put this book where it can be reached at any time, to use it over a long time.

Guarantee:

1. The WPM-2008A2 Stripping & Terminal Crimping Machine’s guarantee period is 12 months from the day of shipment.

2. The guarantee clauses will not include the damage resulting from the falling, rectification and improvement, improper installation or insufficient usage, service misdirection operation, or machine operation errors.

3. Conveyance and packing charges are paid by the customer.

1. Generally safe rules

The following " dangerous", " warning", " attention", and " reference" are defined as follows:

Dangerous: dangerous circumstances where the wrong operation will cause the personnel to die or suffer from a severe wound.

Warning: dangerous circumstance where the wrong operation will cause the person to suffer from a severe or slight wound.

Attention: dangerous circumstances where the wrong operation will cause the person to suffer from a slight wound or cause the articles to be damaged.

Reference: cautions on operation and maintenance.

Please obey the warning items that this book contains.

1-1 Cautions before installation

Attention

Please read this book in detail before installation and operation of the machine.

Attention machine working environment instruction

1. Let the equipment work in an environment that is clean, without dust, has no caustic chemicals, and without strong electromagnetism field interference. Do not place it in a very cold or very hot environment. Keep good ventilation.

2. Electric voltage, frequency deviation. (0. 95~1. 05 AC 220 V, 0. 99~1. 01 50 Hz )

3. The adoption of appropriative power supply coming lines and good grounding.

4. If for a long time you don't use the machine, please turn off the total power supply, and pull out the power supply plug.

5. Working environment temperature (5-40 ° C )

6. Working environment's humidity (<=50% @40 ° C or 90% @20 ° C)

7. Conveyance and storage environment temperature ( long time:25 ° C~55 ° C /short time:/70 ° C).

1-2 Cautions before running

Attention

Notice

1. This machine is the professional equipment to process the bushing used in the fields such as cars appliances and communication, etc. This equipment can implement the functions of automatic feeding, measurement, and testing.

Attention Notice

2. Users will never be allowed to reform the machine's mechanisms or electric circuit etc., as it will cause the equipment to be in disorder and unable to carry out a normal function or even bring to the human body some damages that can't be anticipated.

3. Users shouldn't remove the safety device or the rear cover, or change the position of installation.

4. The user shouldn't wear any loose clothing or wear any personal adornment; otherwise he will suffer from every wound because of touching the top of the machine.

1-3 Cautions during running

Attention

Safe cautions

1. The cutting knife and roller work state when the machine is running. So absolutely stretch the manual or finger into the connection box or protection cover to touch the cutting knife or rollator to avoid any unnecessary danger.

2. to touch any electric part to avoid any electric shock. Only professional personnel can open the cover to carry out maintenance.

3. machine's weight is about 100 Kg. To move it may be dangerous!

Attention 4. When operating on the cutter holder or the blade, turn off the power supply, and pull out the power supply plug. And don't put the manual or finger inside the protection to prevent the blade from wounding the finger.

5. When replacing the processed material, please turn off the power supply and pull out the power supply plug.

6. When removing the waste inside the cutting knife, turn off the powerplay, pull out the power supply plug, and use a manual tool to do it.

1-4 Repairing and maintenance

Attention

1. Please pull out the power cable while carrying on electric circuit checking etc. Please do not carry on any operation, while the power is on, to avoid the electric shock.

2. When replacing the cutter holder or other mechanic parts, turn off the power supply, and pull out the power supply plug, to prevent the blade from wounding the finger and avoids electric shock.

3. While just ending the processing, the motor temperature is still very high, therefore you should not touch it.

During the whole machine working process, especially when it's just started, do not wear gloves during operation, prevent the gloves from being drawn in. Dangerous!

2. Introduction

The machine adopts advanced electronic control technology, with a high-precision control module and transmission mechanism, it helps strip and crimp at one-time and also with low noise, low power consumption, high efficiency, and so on. For extremely thin wire, the processing of multi-core shielded wire has an obvious effect. The wire range is AWG 18-36.

The machine wire stripping action is driven by cylinder transmission, with high speed and accurate position. By using the vacuum suction mode, Waste is clean, convenient, and simple. The press is driven by a gear reducer, and the pressure is highly accurate. For an un-proficient or proficient operator, the machine can be adjusted by changing the overall speed of the gas valve, to adapt to the operator's proficiency.

It is our aim that it can reduce the working procedure effectively, reduce the difficulty of the work and improve the working efficiency. At last, we wish to make progress together with colleagues from all.

3. Specifications and function parameters

Model WPM-2008A2

Crimping capacity 14.7kN

Stroke 30mm

Power AC220V ±10%, 50Hz

Motor 1φ 230V 250W 4P

processing Wire range AWG36~16

Main body dimensions 375 mm x 365 mm x 435 mm

Weight Approx.88 kg

4. Adjustment

4-1 Terminal applicator adjustment: remove the applicator, adjust the terminal and the cutter seat, make the terminal hind feet and core cutter edge alignment, then adjust the feed length.

4-2 Pressure adjustment: 【manu/auto】 key indicator light in a red state, directly press the up/down key, repeatedly adjust pressure height until the requirements. During the adjustment, Please confirm that the compressed air manual switch (manual valve) is closed. Press 【manu/auto】 key when the punch stroke is more than half, light in the green state, and step on the pedal punch can auto reset (back to the origin).

4-3 Cutting depth and length adjustment: Adjust the screws according to figure (1) (3), get the right position, and then tighten the fixing screw, and test the 【clamp/cut】 key.

4-4 Fixed clamp adjustment: Adjust the positioning screw according to figure (2), get the right position, and then tighten the fixing screw, and test the 【clamp/cut】 key.

4-5 Cutting position and terminal location adjustment, loosen the set screw according to figure (3), get the right position, and then tighten the fixing screw, test the 【strip】 key.

4-6 test the 【test】 key.

4-7 Press the key, the indicator light in the green state, step the panel to work the machine

5. Keyboard

【clear】: To reset the counter. In the working mode, to clear the present count.

【up】In the manual state, upper the slide height

【down】In the manual state, lower the slide height

【set】Choose the parameter to change, beset OK before leaving the factory.

【manu/auto】Manu state for adjustment, auto state for running machine.

【clamp/cut】Independently fix the clamp or cut a wire during adjustment.

【strip】Independently move backward during adjustment.

【test】Independently strip wire during adjustment

【power】power on or off

【light】light on or off

【motor】motor start or stop

【strip】stripping function on or off.

When only need crimping function, Please confirm that the compressed air manual switch

(manual valve) is close and please connect the air source. When the motor and strip are both

on, the step foot panel can run the machine with stripping and crimping functions.

6. Crimping operation process

warning Please cut off the power switch before the finger is put into the applicator. The idle crimping and continuous crimping will damage the blade, pay attention, please.

Please refer to the following items before the operation, and carry on a periodical check on the processed products.

6-1 To measure the core crimping height

6-1-1 Use the core crimping height micrometer.

Fig 6.1 To measure the core crimping height

6-1-2 To measure the insulation height

According to the terminal specifications, use the method same as that of core height measurement.

If there is no specification, fold the electric wire as shown in the diagram below, the crimping height of the electric wire insulation must ensure that the insulation doesn't deviate.

But please notice:

After crimping, do not let the terminal hurt the wire core.

Fig 6.2 To measure the terminal crimping insulation height

6-2 Electric wire and terminal crimping status

6-2-1 To feed the electric wire too deeply causes bad crimping.

The conductor can't be seen

6-2-2 To feed the electric wire too little causes bad crimping.

The resin can't be seen.

The core appearance is bad.

6-3Terminal deformation is bad

6-3-1 There is no tiny raise at the back.

wire cutting

6-3-2Terminal upper and lower curving angle too big

6-3-3Terminal left/right turn-round is too big

6-3-4Terminal waving too big

6-3-5The terminal burr too much

6-3-6The crimping surface with scars

Scars, dints

7. Repairing and maintenance

1. Clean the machine and keep it clean often.

2. Give the machine a slider, and tangent slip group into the lubricating oil regularly.

3. Pull water into the air filter regularly.

4. Clean residual line skin debris every day.

5. Regularly check the machine parts, screw loose and timely reinforcement.

×

Scan to Chat

🤖 AI Assistant

×

End Chat & Send Transcript

English

English Malay

Malay Swedish

Swedish Finnish

Finnish Danish

Danish Norwegian

Norwegian Polish

Polish Greek

Greek